HYPERSCAN

Engineered for speed, accuracy, and real-world versatility

Accelerate workflows and minimise inspection times

Dynamic scanning with optical tracking for handheld and automated operation

Would you like to know more?

HYPERSCAN helps you scan faster, smarter, and with greater flexibility, even when working with large, complex parts in challenging real-world situations.

It combines high-speed data capture with real-time dynamic tracking, multi-mode scanning, and target-free operation, making it easier to capture the features that matter without slowing down.

Whether handheld or automated, HYPERSCAN simplifies your workflow and provides new levels of productivity, accuracy, and adaptability, all in one portable, robust system.

- Boost productivity: Accelerate large-part inspections with high-speed data capture, real-time dynamic tracking, and one-click data transfer, all designed to reduce setup time and keep workflows moving.

- Work with flexibility: Scan in handheld or fixed setups, switch between multi-mode scanning options, and capture accurate data, even when parts are in motion or environments are unstable.

- Simplify integration: Target-free operation, wireless mobility, and full robot compatibility make it easy to slot HYPERSCAN into existing workflows, automated systems, and shop-floor processes.

Watch HYPERSCAN in action and explore what makes it different

HYPERSCAN

Explore the strengths that set HYPERSCAN apart. Boosting productivity, adapting to your needs, and simplifying automation.

HYPERSCAN is purpose-built for high-output environments where (large and medium-sized) parts demand fast, efficient, and consistent scanning. With features like high-speed data capture, dynamic tracking, and optical tracking 3D scanning system, it reduces manual input while delivering accuracy, even in unstable conditions, and doesn’t require the part to be in a fixed position, giving operators greater flexibility and freedom during inspection.

Whether scanning in manual use case or automated configurations, HYPERSCAN keeps workflows moving with fewer interruptions, helping manufacturers maximise throughput and improve efficiency.

From dynamic use across static setups to full freedom of movement. HYPERSCAN offers unmatched versatility across a wide range of scanning scenarios. It seamlessly adapts between manual and automated industrial robot workflows, with multi-mode scanning that allows users to optimise for surface type, detail level, or application need. Its reliable performance even with unsecure parts and in unstable environments gives operators the freedom to move and scan without constraints.

HYPERSCAN is ready for the future of scanning with automation-ready features that support both industrial robot and manual workflows. From batch inspections to high-throughput industrial applications, it enables consistent, repeatable results with minimal operator involvement. With the ability to instantly capture the feature you need, HYPERSCAN streamlines inspection and quality control tasks. Dynamic tracking simplify integration into automated systems, while multi-mode functionality ensures scanning efficiency at every stage.

Any part. Any place. One HYPERSCAN

Features and benefits

Real-time dynamic tracking

HYPERSCAN’S real-time dynamic tracking capability keeps productivity high even when conditions aren’t perfect, continuously compensating for movement, or part rotation during scanning.

Multi cameras/tracking devices

Extend scanning volume and scanning efficiency. HYPERSCAN streamlines setup, reduces preparation time, and removes constraints, helping teams stay productive in fast-paced environments.

Resistance to Instability

Designed to thrive in challenging conditions, HYPERSCAN maintains scan accuracy even in the presence of vibration, part movement, or unstable setups. It ensures reliable results in the real-world environments where other systems fall short.

Ergonomic handheld design

Lightweight and comfortable to hold, HYPERSCAN is built for fatigue-free use during extended scanning sessions, making it ideal for handheld workflows on the shop floor or in the field.

Multi-mode scanning

Built to adapt instantly to the demands of your part with a flexible range of scanning modes, including Standard, Fine, Line, Edge Detection, and Hole Flash capture everywhere required. Whether you're inspecting smooth surfaces or capturing complex details, multi-mode scanning ensures the right data quality every time, boosting both efficiency and accuracy across varied applications.

Applicable accuracy

With precision tailored for medium and large complex parts, HYPERSCAN delivers the right level of accuracy without unnecessary complexity. It balances speed and detail to meet inspection needs across demanding industrial applications.

Intelligent voice assistance

HYPERSCAN’S built-in voice assistant guides the operator through each step of the scanning process, enabling hands-free control and real-time feedback. This allows users to stay focused on the part, streamline their workflow, and reduce errors.

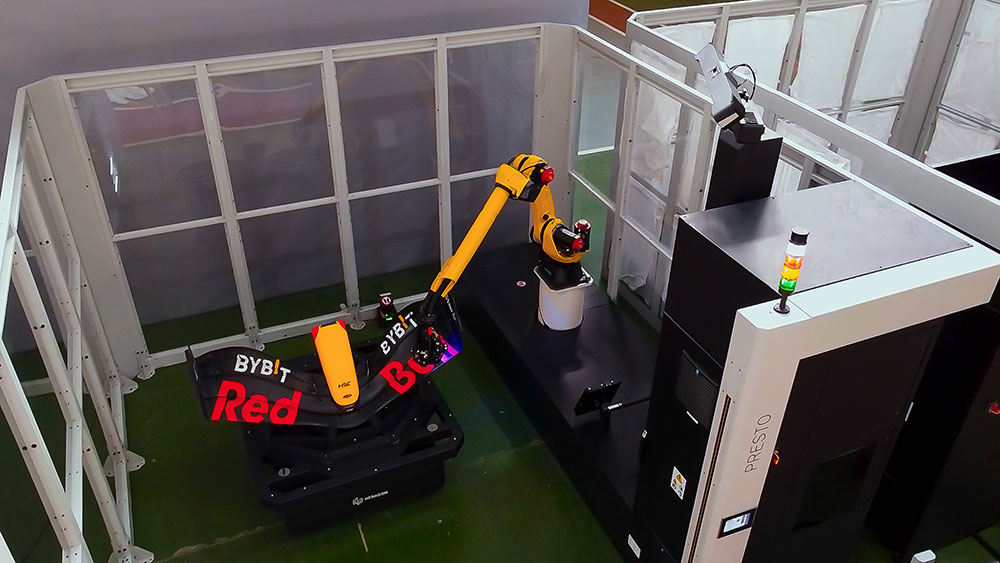

Manual and automated

Seamlessly transitions between handheld use and full robotic integration, giving you the flexibility to scan parts manually or automate high-volume inspection tasks. Whether used on the shop floor or in an automated cell, it delivers consistent results with minimal reconfiguration.n tasks. Whether used on the shop floor or in an automated cell, it delivers consistent results with minimal reconfiguration.

Wireless scanning module

HYPERSCAN eliminates cable connection with Wi-Fi 6/7 connection with battery autonomy.

Seamless integration

With native compatibility across major software platforms and automation systems, HYPERSCAN fits easily into existing workflows. It simplifies implementation and speeds up deployment for immediate operational impact.

Traceability

The system is traceable to a set of international standard of VDI/VDE 2634-3 with an ISO 17025 certified laboratory.

Highly portable and robust

The compact, robust design makes it easy to transport, deploy, and operate in the field or across multiple sites. Built to withstand industrial use, it’s as reliable on the shop floor as it is in remote environments.

-

The HYPERSCAN series

HYPERSCAN Super:

Up-to 7m tracking range

- Real-time dynamic tracking ability

- Target free scanning solution

- Looking for cost effective automation and ergonomic handheld scanning

HYPERSCAN Ultra:

Up-to 5.5m tracking range

- Real-time dynamic tracking ability

- Target free scanning solution

- Looking for cost effective automation and ergonomic handheld scanning

-

Downloads

-

6 reasons to choose HYPERSCANVersatility

Designed for real-world conditions, HYPERSCAN adapts to your workflow with handheld or automated, multi-mode scanning, and the ability to scan moving parts. It’s the all-in-one solution for diverse surfaces, sizes, and environments.

Speed

HYPERSCAN delivers rapid, high-resolution data capture with minimal setup. Its target-free design, automated feature detection, and multi-million point-per-second scanning drastically reduce inspection time, keeping your workflows fast and fluid.

Precision

Whether scanning large structures or fine features, HYPERSCAN delivers the right level of accuracy for reliable results every time. Built-in edge recognition and Hole Flash capture ensure no detail is missed, even on complex geometries.

Automation

From robotic integration to pre-configured automation settings, HYPERSCAN is ready to scale with your operation. It fits effortlessly into automated inspection cells and smart manufacturing systems, enabling consistent, hands-free scanning.

Mobility

HYPERSCAN’s wireless scanning module and ergonomic design offer complete freedom of movement. Easily navigate large parts, work in tight spaces, or take the scanner where it’s needed most — all without being tethered to a station.

Accuracy

HYPERSCAN delivers the precision you need for confident decision-making, from fine feature inspection to large-part analysis. With advanced edge detection, Hole Flash capture, and stable performance even in motion, it captures accurate, repeatable data you can rely on across every scan.